Vacuum Valves

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vaccum Valves |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SMC Pneumatics supplies your facility with top quality vacuum air valves with numerous specifications and sizes.

These vacuum valves are a critical component of pneumatic systems including:

- Industrial pumps

- Factory and plant equipment

- Lage boats

- Certain cars and other vehicles

…and many more.

Vacuum-based machines like vacuum cleaners use these valves. Most people have encountered this piece of equipment if they ever took apart an older style of vacuum cleaner to clear it of debris or replace a part. View rugged vacuum valves with full technical specs from SMC Pneumatics here.

Notes On SMC Pneumatics Vacuum Valves:

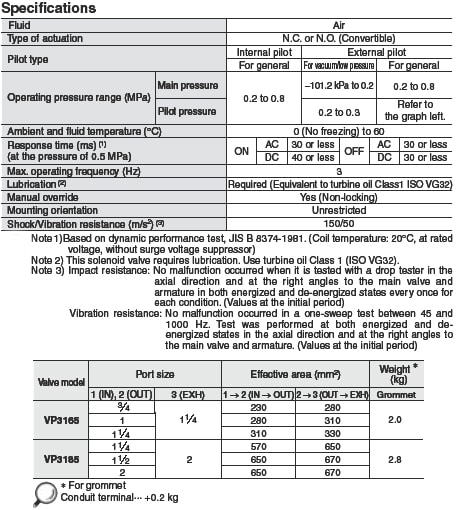

- According to dynamic performance tests, JISB 8374-981. (Coil temperature 20°C at rated voltage, with no surge protector.)

- Solenoid valve must be lubricated. Please use turbine oil Class 1.

- Impact resistance: No malfunction occurred when it is tested via drop tester in the axial direction and at right angles to the main valve and armature in both energized and de-energized states every once for each condition.

Vibration resistance: No malfunction occurred in a one-sweep test between 45 and 1000hz. The test was performed at both energized and de-energized states in the axial direction and at right angles to the main valve and armature.

More specs:

- Resistance to shock & vibration: 150/50 (M/s2) (3)

- Mounting orientation: Unrestricted

- Manual override: Yes, non-looking

- Lubrication: Required (Equal to turbine oil class)

- Fluid type: air

- Actuation type: N.C. or N.O.

- Ambient and fluid temperature 0 to 60°C

How A Vacuum Valve Operates: An Explanation From SMC Pneumatics

You need vacuum valves in systems that operate by directing the flow of air and fluid to generate a vacuum. Vacuum valves work within equipment that makes use of gauges and switches to manipulate the flow of air or pressure inside the valve and release the pressure when it is needed within the system. The operator uses a switch mechanism to open the valve.

How To Know When You Need A Vacuum Valve

Vacuum valves are used when you need to keep a vacuum going within a closed system. They are also used for more hands-on purposes such as manipulating gas flows within a chamber, isolation, ventilation, or to provide relief and control conductance.

Among vacuum valves there are:

- Gate

- Inline

- Angle

…and more varieties of valves are often used for high volume systems.

Additionally, you’ll find valve types such as:

- Ball

- Butterfly

- Conductance controllers

- Diaphragm

- Gas control

- Leak valves & straight through.

How Do I Know Which Vacuum Valve I Need?

SMC pneumatics is always ready to offer guidance with questions like these. However, here are some general notes to assist you:

Gate Valves: The Advantages And Disadvantages These Units Offer

Gate valves are also called knife valves or slide valves. They are linear motion valves in which a flat closing element slides into the flow stream to deliver shut-off. Meanwhile, in-line valves have their inlet port located parallel to the outlet port, and it may or may not be axial with the inlet port. The advantages of gate valves are that they are available in large sizes, may be used in slurries or viscous fluids, and they are easy to care for. The disadvantages include low-pressure limitations, a slow open and close time, and potential erosion in the disc and seat.

Angle Valves: How To Know When You Should Use Them

Angle valves have their inlet port set at a right angle to the outlet port. Ball valves are quarter-turn, straight flow valves with round closure elements with matching rounded seats that make uniform sealing stress possible. You should use these valves if you are dealing with a fluid that will sometimes have a pulsating flow.

Butterfly Valves: Which Industries Use These Valves?

Butterfly valves are fast-opening valves that comprise a circular metal disk or vane with its pivot axes at right angles to the directional flow inside the pipe, which when rotated on a shaft becomes sealed by pressing against seats in the body of the valve. These are used in industrial processing and production equipment for the chemical, pharmaceutical, food industries, and much more.

Conductance Controllers: A Key Component Of Vacuum Systems

Conductance controllers adjust the conductance through a vacuum system by modifying the most common available path to the gas molecules. Diaphragm valves divide the flow stream from the closing element using a flexible diaphragm, as the name suggests.

Gas metering, throttling or leak valves all control the flow of gas into chambers or processing vessels. Vacuum or pressure relief valves guard chambers or components against excessive pressure that could warp or damage the component. Straight-through valves have inlet ports situated at a parallel to the outlet port as with the inlet port.

More Expert Information On Vacuum Valves From SMC Pneumatics

SMC Pneumatics offers vacuum valves in a wide range of sizes, and we are happy to help you figure out which one you need. SMC Pneumatics provides industrial operations of all kinds with durable, long-lasting pneumatic equipment including vacuum valves. Contact us online to learn more about the equipment above, applications, or to get the answers to any questions you may have about which valves you need.