The Elon Musk Hyperloop project may well be one of the most challenging uses of pneumatics systems and technology ever, and one of the largest. The basic idea behind the Hyperloop project is not new from an engineering and physics standpoint. What is new, is the scale to which pneumatic systems are to being applied, and the beneficial impact this application of general pneumatics could have on people’s everyday lives. Do you think pneumatic trains are possible?

Creating Your Own Pneumatics System

Typically, when someone like Elon Musk comes up with an innovative idea such as this one, the critics are quick to say that it is not practical, it will cost too much, or it simply cannot be done because the technology is not there to do it.

In this case, the technology is there, and has been for more than a century. Practical uses of pneumatics have in fact been around for several centuries. Consider the common straw. When you sip a soda through a straw, you create a vacuum which draws liquid up into the straw. More accurately, the external air pressure, pushing down on the liquid, causes it to rise up into the straw. When you blow into the straw, the direction of the liquid reverses. You’ve created a bi-directional pneumatic system in miniature.

The challenge Musk faces is to take the physics of sucking and blowing through a straw, and apply it to a several hundred-mile-long system of pneumatic trains. This has actually been done before, although on a smaller scale. Pneumatic trains successfully operated for more than a year in London in the mid-19th century, and a block-long pneumatic transit prototype operated in New York in 1870. In London, steam-powered fans were used for propulsion. In New York, movement was created by a pressure differential – low air pressure in front of the car, higher air pressure behind.

A Man Who Excels at Putting Concepts into Practice

One of the amazing aspects of the Hyperloop is how quickly it progressed from concept to initial construction – approximately one year. Apparently, Mr. Musk has little patience with naysayers, or those who would accuse him of arm-waving. His record as founder and CEO of SpaceX, co-founder and CEO of Tesla Motors, Solar City chairman, and co-founder of PayPal, would indicate that Elon Musk is a person who know how to get things started, and how to get things done.

Challenges to Overcome

There are many challenges in taking a small-scale pneumatic system like those in use today in banks, hospitals, and factories to move money and documents, drugs and lab samples, and parts, respectively, and replicating it on a much more massive scale.

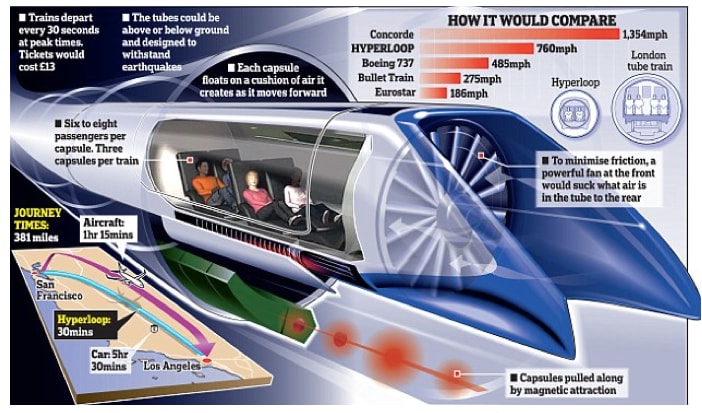

One of the challenges is attempting to maintain a vacuum in a large tube that covers a great distance. Maintaining a total vacuum is not only costly, but nearly impossible. On the other hand, maintaining a low pressure system is practical and quite adequate. The ability to create a low air pressure environment overcomes the problem of forcing a transport capsule to push a long column air ahead of it.

Another challenge is that of overcoming the Kantrowitz limit, which defines the top speed a capsule can achieve for a given capsule diameter to tube diameter ratio. The challenge is that of creating just the right spacing between the walls of the capsule and the interior walls of the tube to avoid a syringe effect that would tend to force the capsule to slow down as it is propelled along.

Musk’s approach is to allow the capsule to travel in a partial vacuum, ride on a cushion of air, and be propelled by a fan. The fan will be powered by a combination of solar power-produced electrical energy stored in batteries, and compressed air stored by a reverse fan when the capsule is in motion. The system is self-sustaining in terms of energy, and will actually produce a surplus.

Where is the Elon Musk Hyperloop Project now? Construction of a 5-mile California test track is underway, and a capsule (pod) competition is scheduled to take place later this year. The test track costs about $150 million and will take 32 months to complete. <Video>

The Benefits

For distances up to about 900 miles, travel will be cheaper. It will also be faster, since when using supersonic aircraft for short distances, most of the time will be spent ascending and descending, with little time remaining to operate at cruise speed. With passengers, the Hyperloop capsules or pods will move along at 160 mph; when empty, the pods can be moved at speeds of up to 760 mph.

Using pylons (from Los Angeles to San Francisco), is far less expensive than constructing a rail line, including having to purchase land for easements; plus, you don’t have to worry about a loose track or hitting a cow.

For those who wonder how general pneumatics systems might be placed in operation in a truly large and complex scale, the Hyperloop shows it can be done, as well as how practical and beneficial these systems can be. Keep in touch. You never know what Elon Musk may come up with next.

SMC Pneumatics USA, powered by Orange Coast Pneumatics Inc. (ocaire.com), is a National Elite distributor for the SMC Corporation of America. SMC offers 11,300 general pneumatics products, with over 560,000 variations, engineered to meet applications in every sector of the market. From Semiconductor to Automotive, Medical to Petroleum, SMC's products are designed to fit your unique requirements.

If you would like more information on our products and services, please visit us at our Website, Facebook, Twitter, LinkedIn, and Google+. We look forward to serving your pneumatics needs.